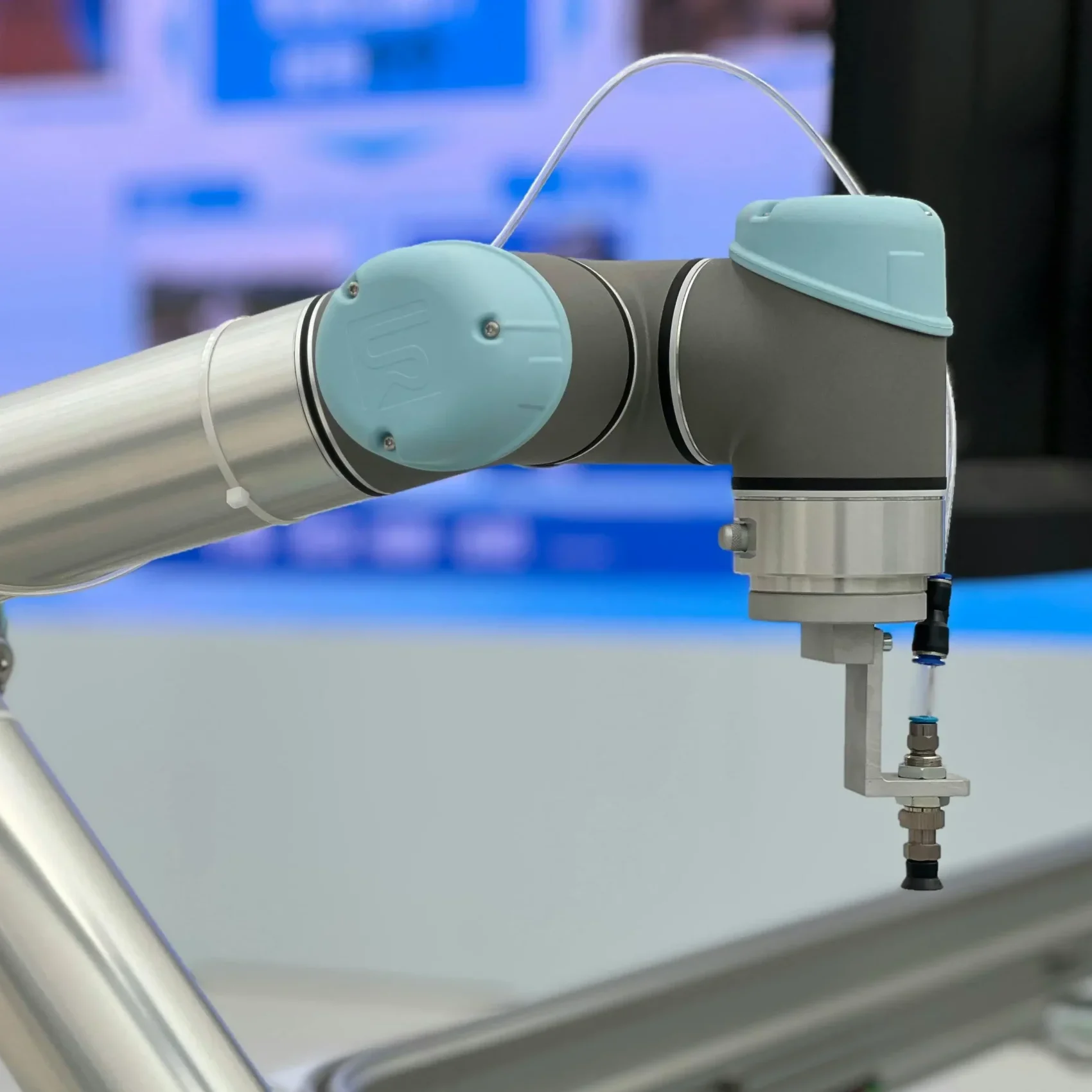

Machine vision cameras have become an essential component of numerous industries, with a large variety of applications. These cameras are designed to capture images and videos that can be analyzed to automate different industrial processes. To meet the demands of industrial inspection applications, machine vision cameras must meet the requirements of specific applications, and are typically small form factor and low power. Since the focus of machine vision cameras in industrial inspection is to increase productivity by reducing downtime, many machine vision systems pay for themselves quickly with a high return on investment.

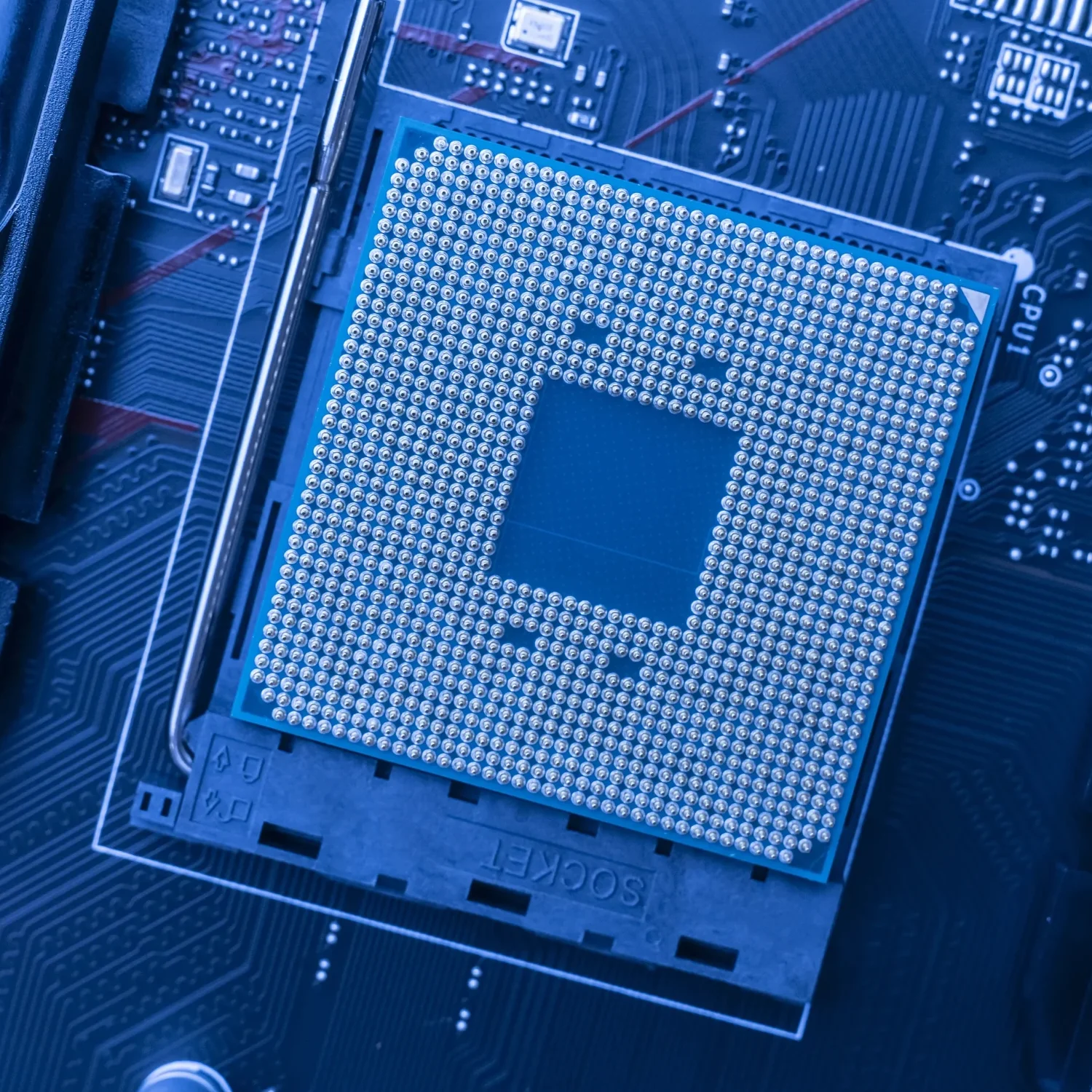

The most critical features of machine vision cameras are resolution and speed.. Industrial machine vision cameras must have high-resolution imaging capabilities to detect small defects and measure dimensions accurately. Also, cameras used in different inspection applications must be capable of capturing images at high frame rates to provide maximum throughput of the machines. Therefore, cameras must have a very high data transmission speed, allowing the software to make decisions in real-time, and minimize the time between image capture and analysis. KAYA cameras are designed for fastest system throughput for machine vision software to make decisions such as fastest data transport (CXP-12), on-board pre-processing and the KAYA frame grabbers are compatible with all known imaging libraries.

Often the cameras work with image processing software, which requires the best conditions and image quality to provide a reliable result.

Finally, machine vision systems must be reliable and durable. Cameras and frame grabbers must withstand harsh environmental conditions, including extreme temperatures, shock, and vibration.

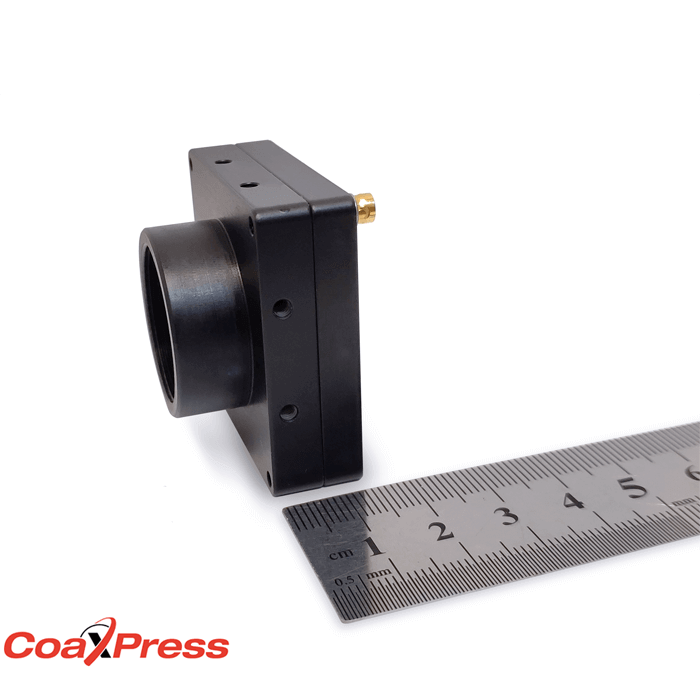

KAYA Vision is a leading machine vision camera manufacturer, offering a range of high-performance cameras and frame grabbers specifically designed for industrial machine vision applications. Our cameras are a small form factor and low power, making them ideal for use in tight spaces and challenging environments. KAYA’s cameras utilize advanced global shutter CMOS sensors, ensuring excellent low-light performance and high image resolution necessary for quality inspection purposes. Additionally, KAYA’s cameras are designed to provide optimal quality video under even the most severe conditions, making them the reliable choice for industrial quality inspection applications.

Machine Vision

Related Articles

-

Megapixel Vision Bottlenecks Solved

-

Choosing a High-Speed Defect Camera

-

Balancing FPS and Resolution

-

Choosing CoaXPress Ultra-High-Resolution Cameras

-

150-MP Pathology Cameras

-

Rugged Compact Cameras

-

Choosing High-Speed Cameras

-

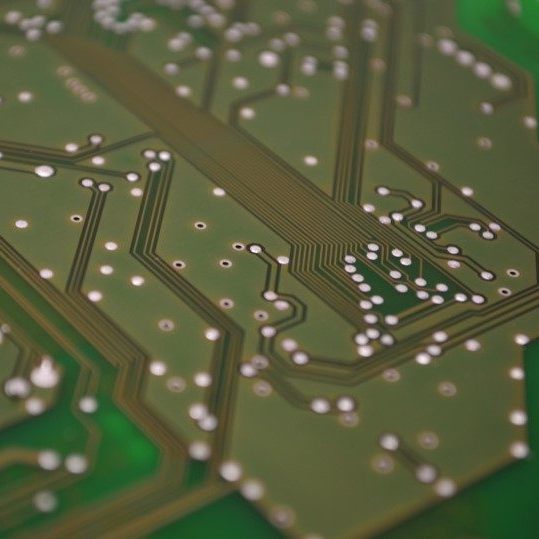

Ultra-Resolution PCB Imaging

-

Pick High-Speed Cameras

-

Smart Port Machine Vision Navigation

-

Deep-Sea Vision Cameras

-

High-Speed Fish Processing Vision

-

Rugged Vision for Autonomous Vessels

-

AUV Hull Imaging with KAYA Cameras

-

Rugged Vision for Heavy Manufacturing

-

Edge AI Cloud Cameras

-

Pixel Pitch vs Sensor Size

-

Machine Vision for Maritime Hull Monitoring

-

Choosing Cameras for Wafer Inspection

-

24/7 Port Container Vision

-

Best CoaXPress Cameras 2025

-

Fast Port Cargo Inspection Cameras

-

Machine Vision Stops Whale Collisions

-

Compact Cameras for Stadium Tracking

-

Agro-Drone Imaging Revolution

-

Machine Vision Navigation for Autonomous Aircraft

-

Streamlining Custom Machine Vision Projects

-

KAYA Consultation: Concept-to-Camera

-

Retrofitting Legacy Lines with CoaXPress

-

24/7 Rugged Vision Design

-

CoaXPress 2.0 Unleashed

-

Building Ultra-High-Resolution CoaXPress Systems

-

Choosing High-Speed Cameras for Inspection

-

Energy-Smart Inline Vision Cameras

-

Heavy Duty CoaXPress Cameras for Industry

-

Ultra-Compact Industrial Cameras for Workcells

-

CoaXPress Traffic Camera Upgrade Guide

-

Cameras for Traffic Safety

-

Building Compact OEM ANPR Cameras

-

CoaXPress Traffic Cameras Transform Highways

-

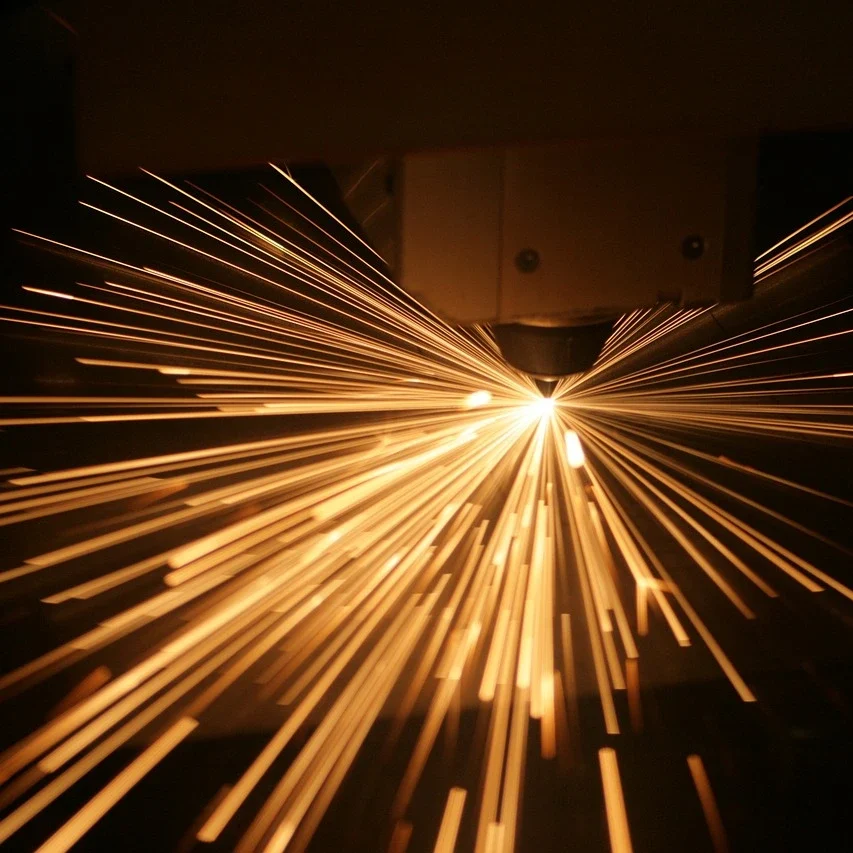

Cameras for Iron Casting

-

Factory Broadcast Imaging Cameras

-

Long MTBF Cameras

-

SWIR Camera for Research

-

SWIR Camera for Industry

-

Object Recognition Cameras

-

Food Inspection Cameras

-

Pill Sorting and Packaging Cameras

-

Automatic License Plate Recognition Cameras

-

Semiconductor and wafer inspection cameras

-

Factory Automation Cameras

-

Healthcare Manufacturing Cameras

-

High Speed Inspection Cameras

-

Aerospace Testing Cameras

-

Long Range Observation Cameras

-

High Resolution Industrial Cameras

-

Industrial Surveillance Cameras

-

CoaXPress Machine Vision Cameras

-

Machine Vision Cameras

-

High Sensitivity Cameras

-

Research Cameras for Meteorology

-

Cameras for Research

-

Low Light Imaging Cameras

-

High Bandwidth CoaXPress Cameras

-

CoaXPress High-Speed Video

-

High Frame Rate Cameras

-

Cameras for Low Temperature

-

Cameras for High Temperature

-

High Speed SWIR Cameras

-

MIL-STD-810 Cameras

-

Industrial High-Speed Cameras

-

Cameras for Motion Analysis

-

Industrial CoaXPress Cameras

-

Cameras for Harsh Environments

-

Quality Control Cameras

-

Shrink your Vision System

-

SWIR Imaging: Challenges and Technological Breakthroughs

-

PCIe Vision Systems

-

FPGA IP Core: Make vs Buy

-

KAYA Cameras for Lab

-

Industrial Troubleshooting Cameras

-

Is Smaller Better in Imaging Technology?

-

Comparison: CoaXPress vs 10GiGE

-

CoaXPress Over Fiber